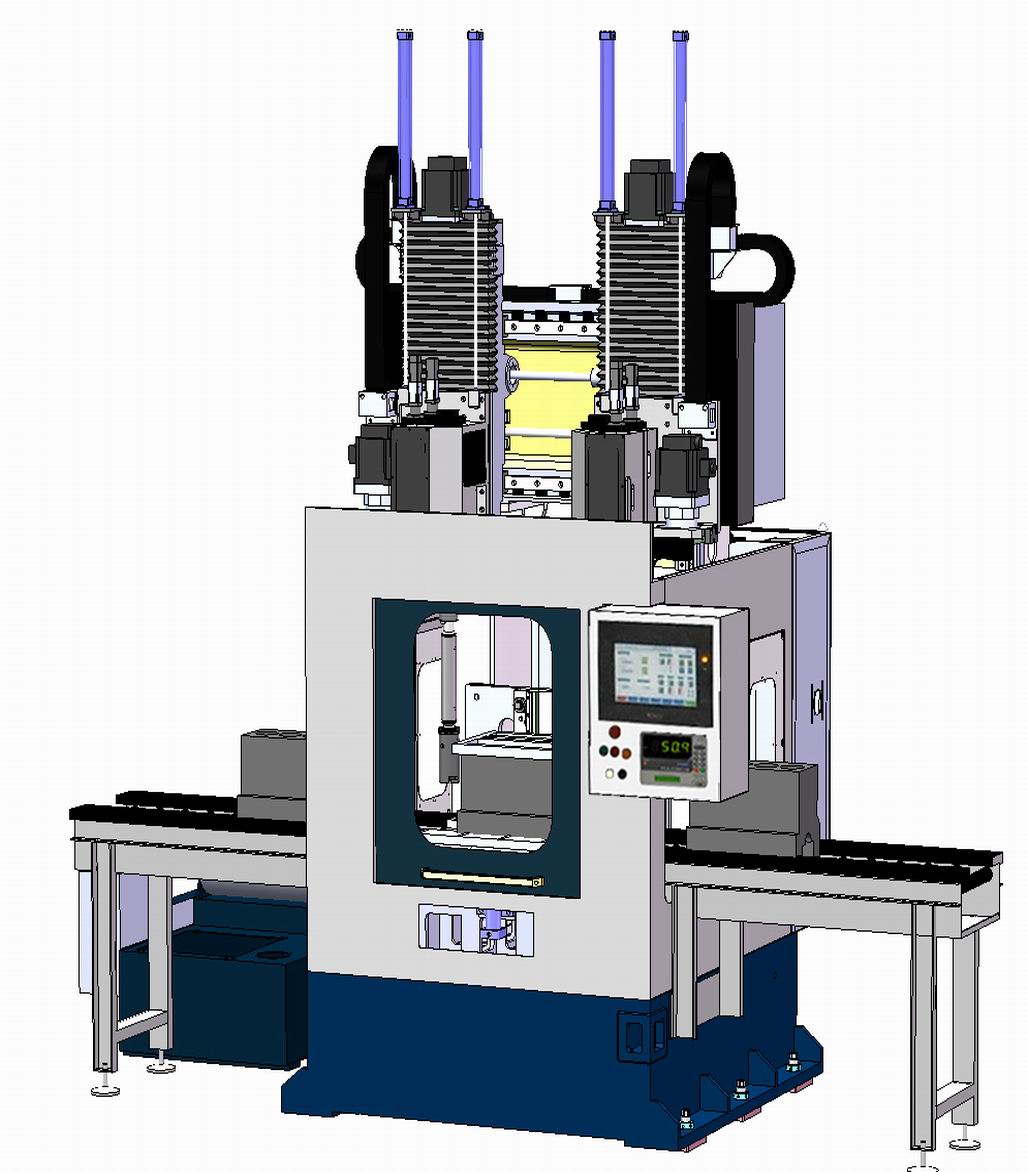

CNC Vertical Honing machine for small hole honing

Category: CNC Honing Machine.

Tag: small hole honing.

MODEL NO.: MG60-1 High Accuracy Vertical Honing machine

Main Technical Parameters

| No. | ITEM | NAME | DATA |

|

1 |

Structural style |

Number of axes: | 1 axis |

| Number of Stations: | 1station | ||

| Working take max loading: | 500kg | ||

|

2 |

Spindle mechanism |

Control method: | Variable frequency motor + synchronous toothed belt |

| Spindle motor: | 2.2KW | ||

| Honing diameter range: | Φ4-φ60mm | ||

| Slewing range: | 50-2000rpm(Infinitely variable speed ) | ||

|

3 |

Stroke mechanism |

Control method: | Servo motor + Ball screw |

| Stroke motor: | 3.1KW | ||

| MAX Stroke speed: | 40m/min | ||

| MAX stroke depth: | 600mm | ||

| Stoke accuracy: | <0. 1mm | ||

|

4 |

Feeding mechanism |

Control method: | Servo motor + Ball screw |

| Feeding motor: | 0.5KW | ||

| Feeding method: | Constant feeding | ||

| Torque output MAX: | ≥15NM | ||

| Feeding resolution: | 0.1um | ||

|

5 |

Others |

Machine weight: | Around 2,800 kgs |

| Machine size(LxWxH): | 1500×1700×2600 mm | ||

| Noise standard: | Not over 80 db |

Machine Accuracy

- Roundness:≤2um;

- Straightness : ≤3um/100mm;

- Roughness: ≤Ra0.2um。

For the specific machining accuracy, see the drawings to be signed by both sides.

Machine Main components

| NAME | SPECIFICATION | BRAND |

| Controller | PLC | SIEMENS |

| Touch Screen | HMI 7 inch | SIEMENS |

| Stroke Servo motor | 1FKseries 3.1KW | SIEMENS |

| Stroke driver | S120 series | SIEMENS |

| Feeding servo motor | 1FKseries 0.5KW | SIEMENS |

| Feeding driver | S120 series | SIEMENS |

| Spindle Converter | 2.2KW | SFC |

| Frequency transformer | G120C 2.2KW | SIEMENS |

| Linear guide rail | 30 | TBI/REXROTH |

| Rotary spline | RLSF025 | TBI |

| Feeding screw | 20 | NSK |

| Ball screw | VF32/20 | I+F |

| Spindle bearing | FAG | |

| Main low voltage components | SCHNEIDER | |

| Clutch | KTR | |

| Locknut | CLAMPTEK |

Honing process

- Parameters before honing

According to workpiece’s demands, we suggest twice honing to complete

- :Stock for removal:06-0.08mm/Dia;

- :Roundness:≤015mm;

- : Straightness:≤02mm;

- :Roughness:Ra2um;

- :Ensure all positions related to the hole, as honing does not improve the position accuracy of the hole.

2)、Honing process

| No. | ITEM | Rough Honing | Final Honing |

| 1 | Honing bar | D-0.005 | D |

| 2 | Oilstone | DM95 | DM051 |

| 3 | Stock for removal/Dia | 0.02-0.03mm | 0.01mm |

| 4 | Roughness after honing | Ra1.2~0.8 | <Ra0.2 |

| 5 | Roundness after honing | 0.004 | <0.001 |

| 6 | Cylindricity after honing | 0.003 | <0.002 |

| 7 | Fixture | Cradle floating | |

| 8 | processing form | 1pc/ Honing | |

| 9 | Cycle time | Sec/pc | Sec/pc |

Product Class

- CNC Boring Machine

- CNC Honing Machine

- Grinding Machine

- Honing Accessories

- Honing Machine Remanufacturing

- Lathe Machine for Cylinder liner

- Production Line solution

Contact Us

Name: Jason

Whatsapp: +86 13338867379

Tel: 86-514-85106981

E-mail: careway@china.com

jason@china-honing.com

Add: No.69 Jinye Road, High-Tech Zone, Xi'an, China.

Contact us On Line.